Greater Durability

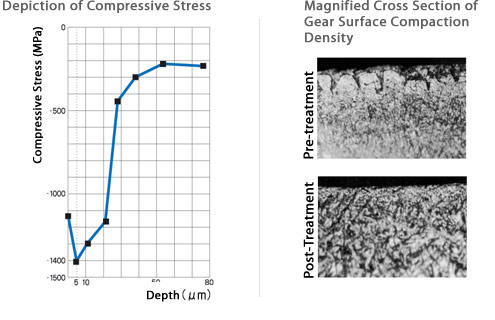

The ultra-fine media of the WPC process, when projected at high velocity towards the product surface, creates compressive stress at the impact points. At the same time, a micro thermal reaction takes place. It effectively seals minor surface fractures. It also allows a condensed surface to form that has improved density due to compaction. This altered and highly compact surface condition overcomes the problem of brittleness, that is usually encountered when metals are hardened.

Benefit of Using Fine Media

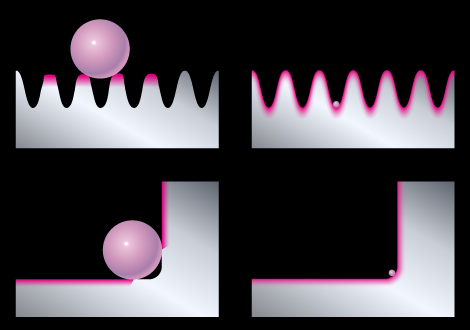

Shot peening (left) and WPC (right)

The numerous impacts during the WPC process not only increase the residual compressive stress but also cause it to reside a lot closer to the surface. The cumulative result is a product that has a durability unrivalled by conventional peening methods.